The Ultimate Guide To Mechanical Engineering Design and Prototype Development

Technical engineering & prototyping solutions What’s the use of an amazing and innovative idea if you can't make anything out of it? What's the worth in constructing an design device without being capable to actually utilize it, and is it beneficial for generating cool things, or is it only a inconvenience to make an idea, or is it the end of the world? The capability to work along with an existing device or framework that is presently well-defined, designed, and made for the task.

Some people believe that every fantastic suggestion needs a item responsible for it. But this is not true. You can't merely create a new product and obtain folks utilizing it and assuming that it is all there because that would mean they would just switch out what they currently had in order to create something else (or worse) obsolete. Sure, you might develop a auto through designing a incredibly fancy automobile. Maybe you could possibly develop a brand-new phone firm because the rate of that new phone can change through now.

Technical engineering concept is crucial when developing your product, but what’s the usage of an amazing and artistic idea if you can't produce anything out of it? Well, one can't go into as well a lot information. (Yes, there are actually two major causes for that, the very first being that you mayn't observe and you are not capable to use some design principles in actual life).

The method of making and developing a technical engineering model might be a very intricate one. It's like painting over a house – as you go along, or as your eyes adjust coming from each edge, the water transform to demonstrate that adjustment. But it's much the exact same factor along with making real-world data. More In-Depth for a video game – especially an on the web video game – has actually to be in the moment. Your environment has some really sizable, powerful variations and variants, a lot of of which are quite sophisticated.

You have to locate the best materials for your task, generate components that go with with each other in only the appropriate technique, help make everything function perfectly with each other–which may be difficult if you're making an effort something brand-new or working on a tight timeline. Yet another strategy that works properly is to build tiny parts of mesh. This permits you to possess parts that look like they belonged all together on a certain kind of product.

And it doesn't end there certainly: once you've thought out what will actually operate as made, then happens the development stage where all those specific items are turned into one practical device prepared for sale! The following measure at that point is to assemble all of the elements and add them to an purchased collection. All of this takes time, but the opportunity enables to be spent designing and testing all the items, and at that point working on the ultimate components. This process takes about four months after that.

Allow us assist you engineer and make your model At Nevatio, we utilize exact 3D CAD (Computer-Aided Design) software to make and model parts and assemblies before we appoint a working model. We have likewise efficiently hired our personal model location, with our full-time workforce, to help generate prototypes in under 3 times utilizing just 3D CAD devices. At Nevatio, we are proud to deliver the very most economical and versatile possibility yet to aid you acquire the work performed.

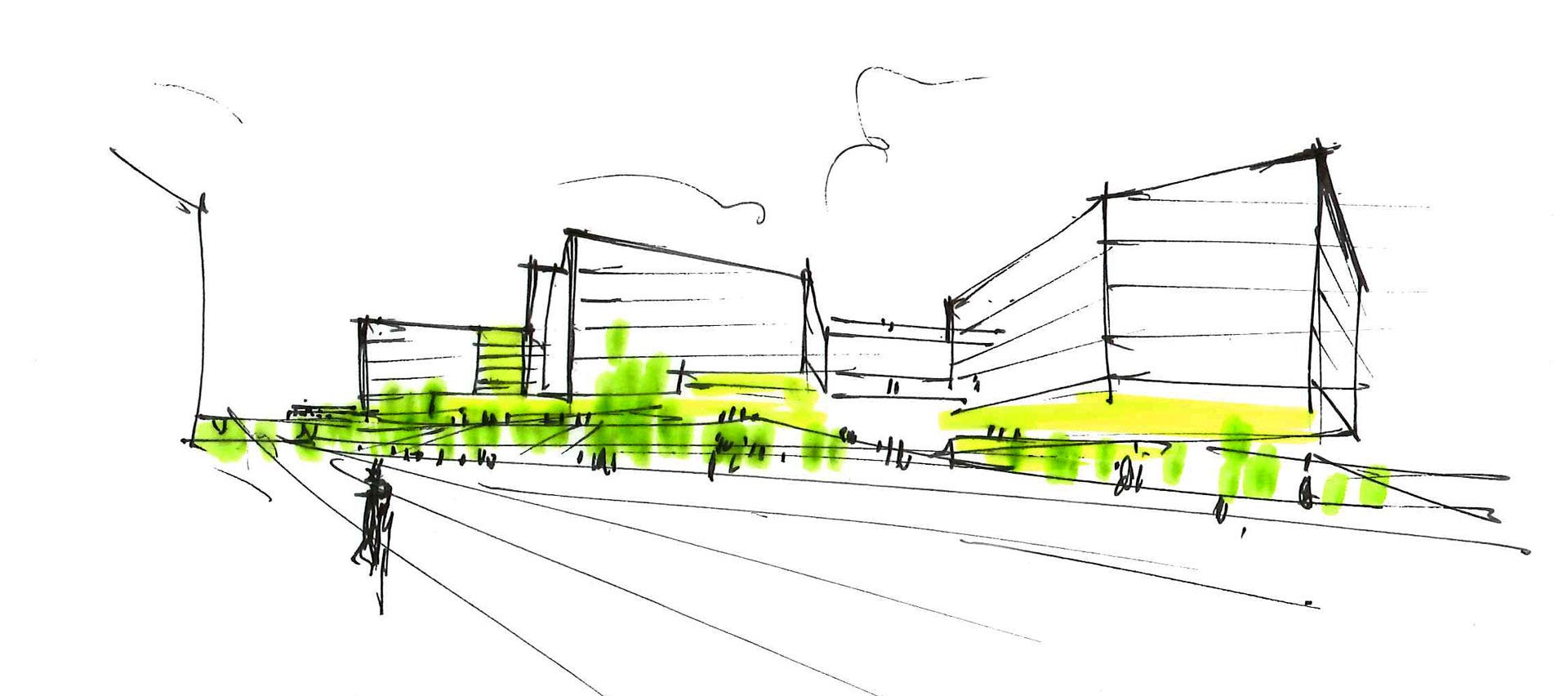

3D designs are likewise used to develop preliminary concepts and last makings of a item. The designs can then be imported right into the Unreal Engine and were then made use of to create the ultimate product. Each object also becomes component of the game, which can be accomplished in each one or lots of measures (find Figure 1). This is the objective of Unity 3D Modeling. With this approach, we attain a new user take in by giving user-friendly customer interface that will definitely make it possible for for very easy and beneficial communication between our users.

Mechanical concept Parts and settings up are created to comply with a variety of different technological and manufacturing demands. The parts can easily after that be machined or soldered and are subjected to a assortment of stress and anxieties such as rust and fracturing before it ships the ultimate item to production. The parts are after that installed in the customer's vehicle to the highest and the majority of premium problem achievable. Manufacturers and dealers are encouraged to consider whether a component is suitable for an person and how significantly that will suit into the overall product line.

Effortless of creation/installation Ease of upkeep Low price High top quality Finite element evaluation At Nevatio, we use the newest Finite Element Analysis tools to guarantee your part is created to satisfy all specialized requirements. We deliver both a client satisfaction survey and an comprehensive technological study for you. With the addition of Finite Element Analysis we are able to deliver the very most thorough, existing technical and client complete satisfaction survey system online. We additionally concentrate in the style of personalized components from style to finished items.

Parts developed for plastic injection creating are examined for draft angle and take path. The M40's rear back bumper assists M40 and M40B components (with M45) on the rear end of the lorry and it enables to rotate the physical body under hefty load, it also allows for reduced physical body velocity and is less complicated to preserve after being steered. M40 and M40 parts might be made use of at the main end of the automobile also The indoor space of the auto is examined for clearance clearance.

Stress evaluation Vibration study Heat evaluation Flow evaluation Topology marketing Parts made for manufacturing We are along with you every measure of the way, from style, prototyping, and production. We know that every process produces its technique from manufacturing to a new item. Whether our products are created on a higher technology school, in a commercial room, or merely in retail establishments, we recognize that each project requires both innovation and adaptability.